| Product | Corporate Information | Factory | Contact us | Access | Top page |

Product

Measuring Instruments

Jigs for Precision Measurement / Outside Diameter Reference Gauge System NEW / Valve seat Face Runout Cheker/ Automatic Measuring Machine/ Vetial Form Checker/ Coordinate Measuring Machine

There are various approaches to measuring instruments according to objectives and purpose. |

Measuring Machine for Small Internal Diameter

|

IDM is traceable to the standard of length

IDM is the best Standard Measuring Machine of Internal Diameter of φ0.1mm to φ100mm.

Measuring Machine for Small Internal Diameter IDM(Optical) |

Measuring Machine for Small Internal Diameter IDM(PAT.)

IDM-100EX

The download of catalogue

|

Precision Indexing Devices

|

High level precision angle indexing devices

This indexing device indexes by means of 720 top and bottom, fully coupled serrations. |

SPID-720

PSID-720A

The download of catalogue

|

Precision Rotary Table

|

High run out precision.

Super Precision Rotary Table SPRT series is a continuous rotary table developed mainly for grinding(but cannot index). |

SPRT-200

SPRT-V200

The download of catalogue

|

Jigs for Precision Measurement

| ISSOKU designs and produces small gaging tools, special gauges and multifunction gauges. |

Cylinder Block Bore Location Gage

The download of catalogue

|

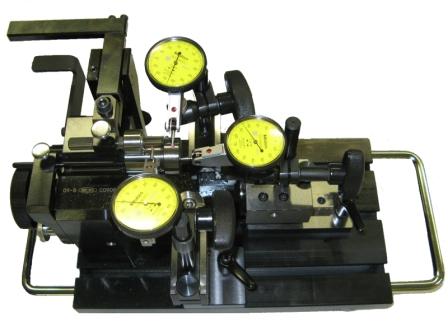

Outside Diameter Reference Gauge System(Runout gauge)

| This gauges measure runout and concentricity of inside and outside diameter. Just put a work piece on main rollers and read indication of dial gauge while turning handle. |

Outside Diameter Reference Gauge System

The download of catalogue

|

Valve Seat Face Runout Checker

| Our original Reference Bar mechanism is incorporated, it is easy to measure runout of seat surface of engine cylinder head with valve guide hole as datum. |

Valve Seat Face Runout Checker

The download of catalogue

|

Automatic Measuring Machine

ISSOKU offers Automatic Measuring Machines with unique technology. |

Internal Spline Diameter Measuring Machine

The download of catalogue

|

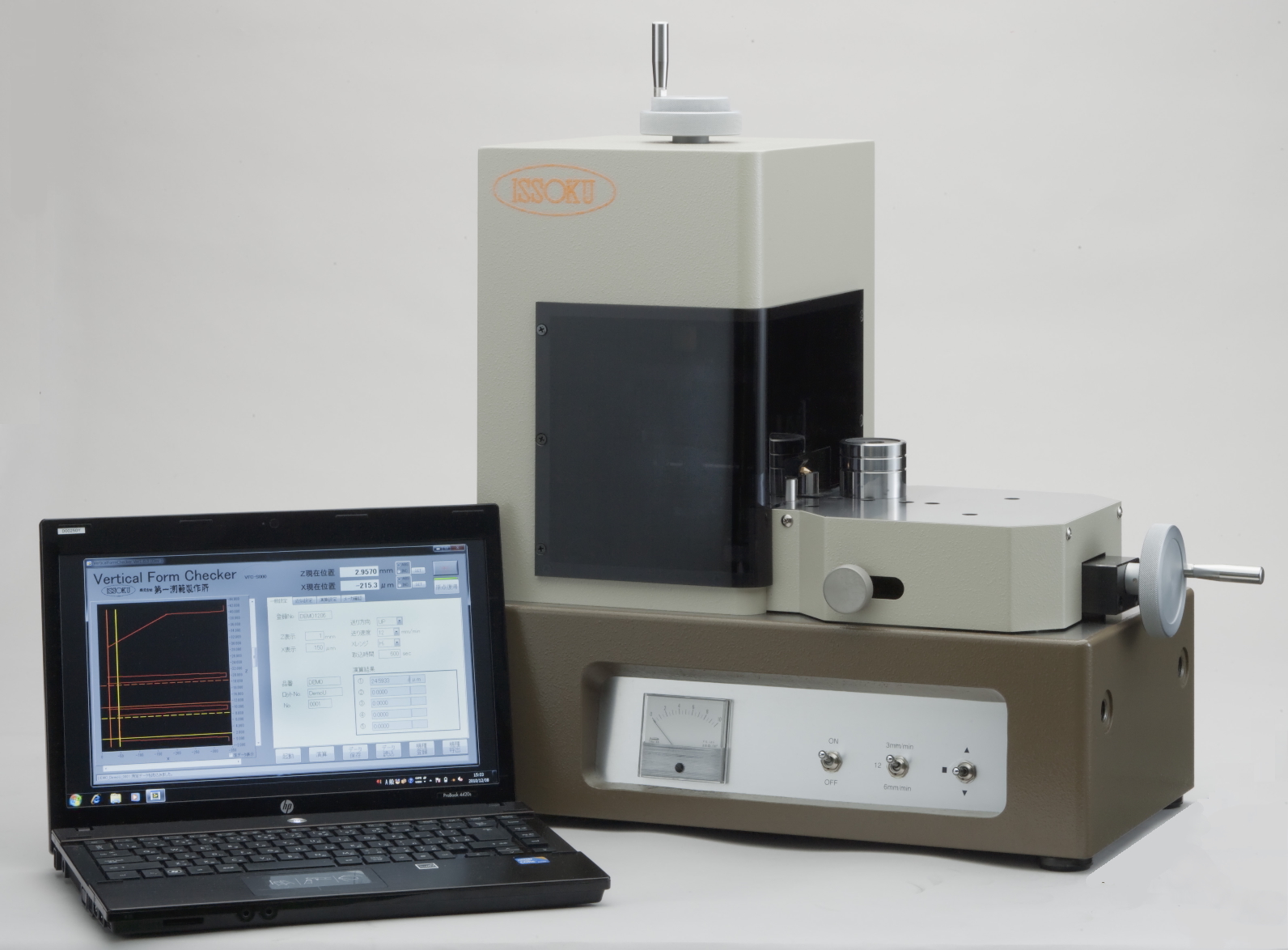

Vertical Form Checker

| Equipped with ISSOKU precision lead screw and high accurate straight template achieve self-correct movement for reliable measurements.The outer periphery of the R and steps of Pisutonringu, including the measurement of the shape of the slope,can be utilized in many shape measurement. |

Vertical Form Checker

The download of catalogue

|

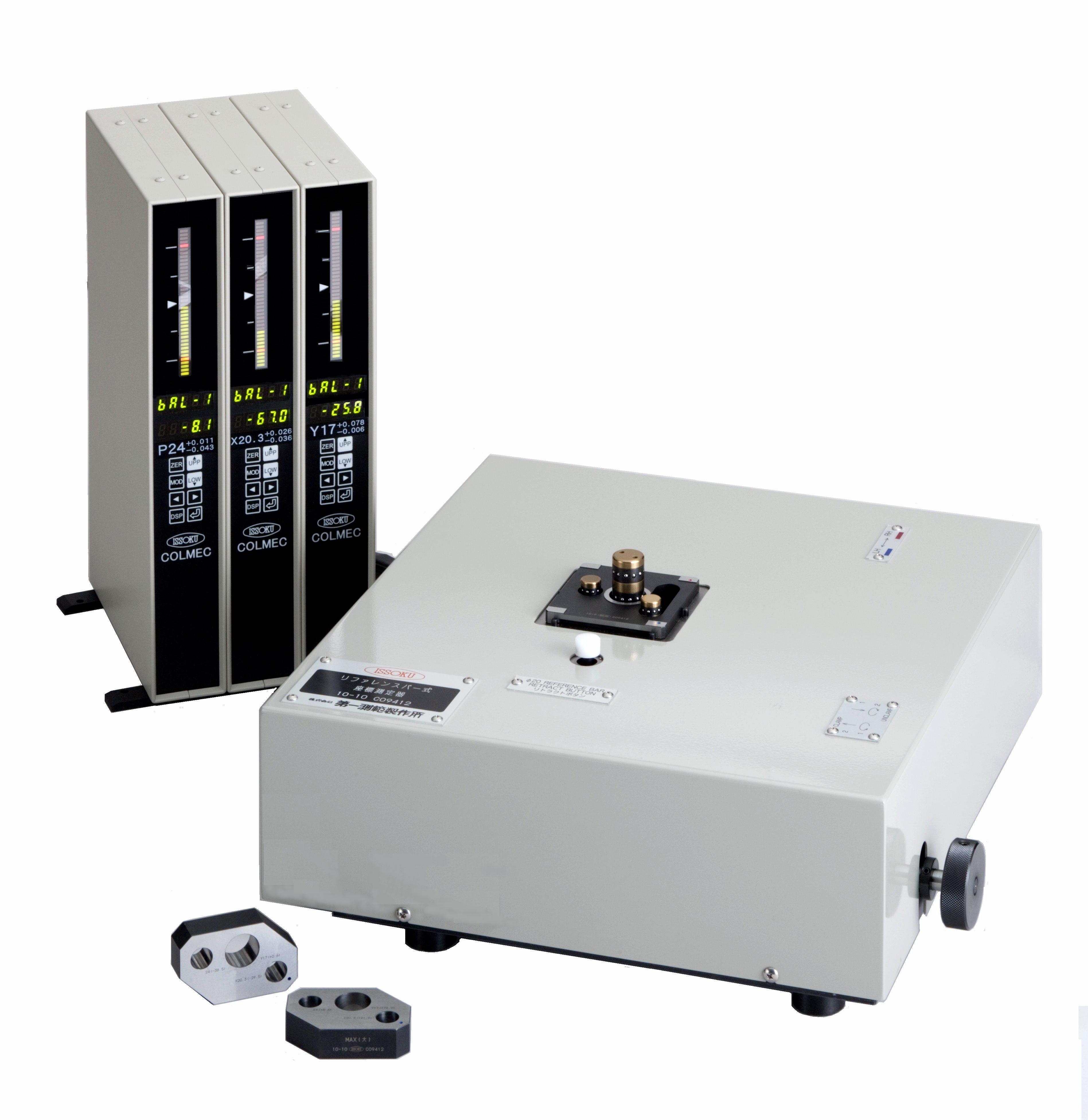

Coordinate Measuring Machine

| Centers of inscribed circle of multiple holes can be positioned by our original Reference Bars (centering jig).Not only pitch between 2 holes also relative position of 3 or more holes can be measured. |

Coordinate Measuring Machine

The download of catalogue

|